Table Blasters

Features:

- These abrasive wheelblast machines use a powered turntable that rotates within the blast envelope to provide 360° exposure.

- The turntable can be swung in and out of the blast enclosure for easy loading and unloading.

- Turntables have abrasion-resistant liners.

- Some models feature an oscillating blast wheel to enhance blast coverage.

- Designed for overhead loading and unloading of heavy parts using a hoist or crane.

Benefits:

- Versatility and flexibility

- Suitable for parts ranging from 10 lb gears to heavy fabrications.

- Facilitate cleaning, peening, deburring, profiling, finishing, and other surface conditioning tasks.

- Provide efficient blasting of parts with consistent 360-degree coverage.

Applications:

- Ferrous and non-ferrous castings

- Heat treated parts

- Automotive parts

- Die Castings

- Deflashing plastic

- Descaling

- Peening

- Deburring

Hanger Blast Systems

Features:

- These abrasive wheelblast systems are designed for batch blasting of parts.

Benefits:

- Ideal for parts that are too fragile or awkward for other automated finishing methods.

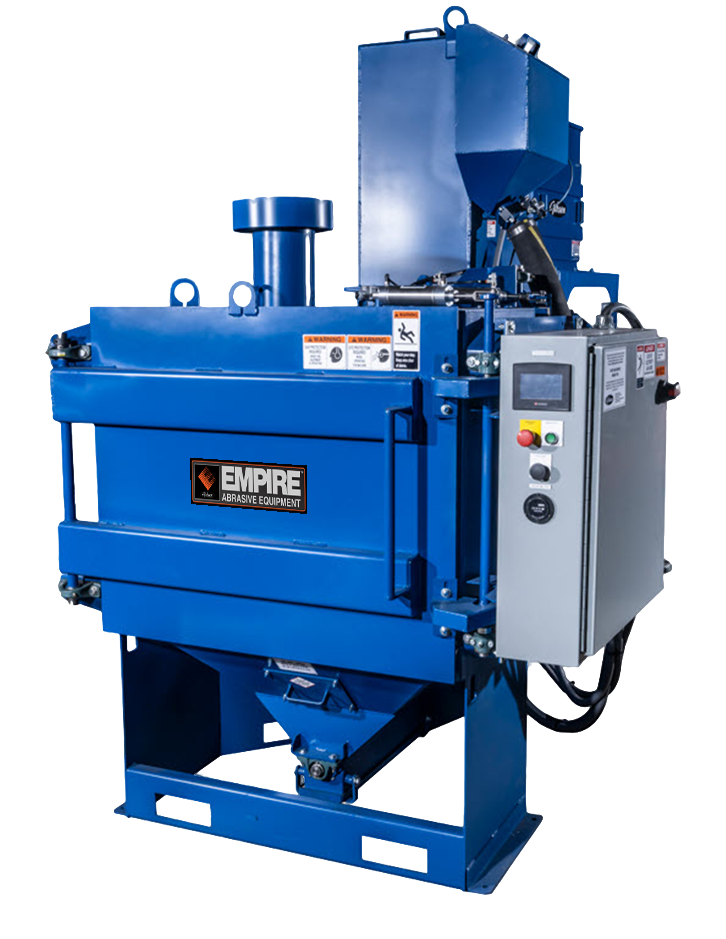

Tumble Blasters

Features:

- Process multiple parts by tumbling them within the blast envelope of this type of wheelblaster.

- Include a perforated belt for loading parts, abrasive-resistant barrel heads, cabinet lines, and door liners.

- Load capacities up to 3,000 pounds or 24 cubic feet.

Benefits:

- Designed for automating surface preparation economically.

- Simple to operate.

- Provide consistent results automatically, whether working intermittently or non-stop.

- Facilitate cleaning, peening, deburring, profiling, and finishing.

Applications:

- Ferrous and non-ferrous castings

- Heat treated parts

- Automotive parts

- Die Castings

- Deflashing plastic

- Descaling

- Peening

- Deburring

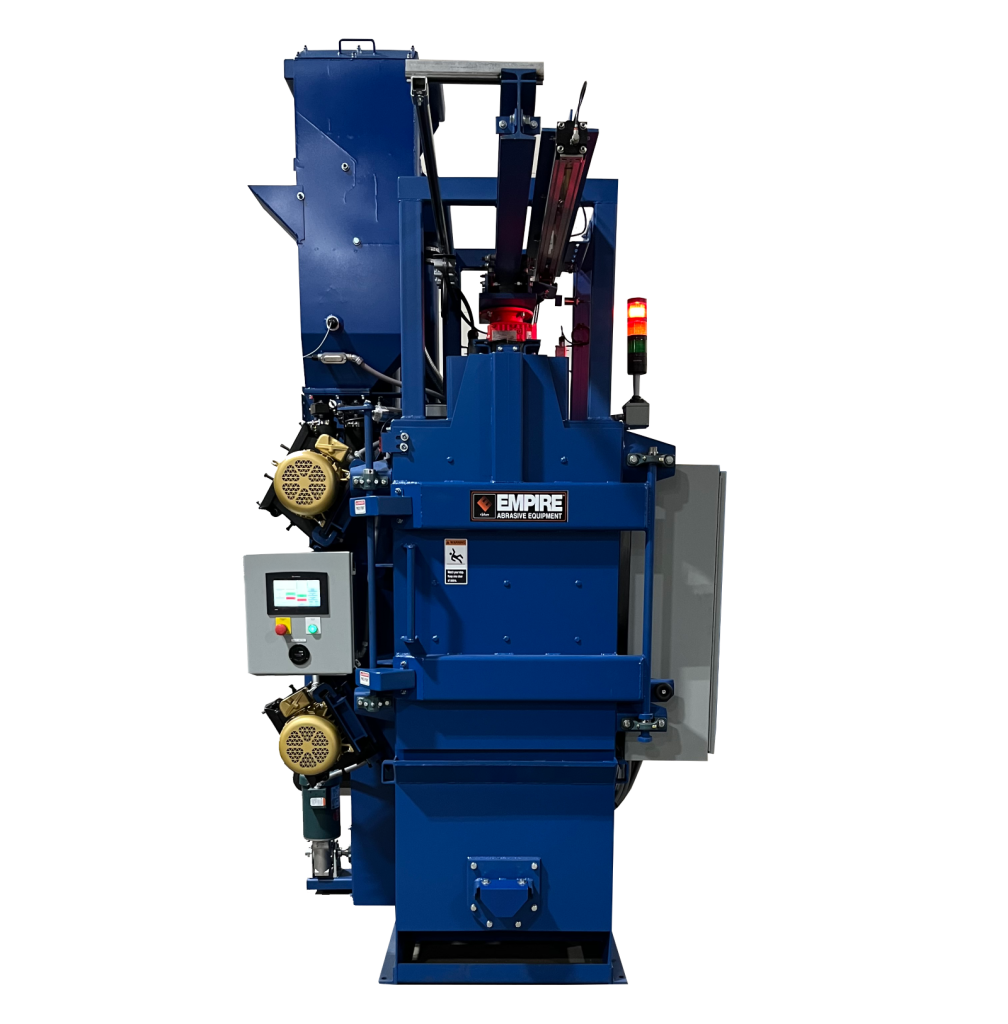

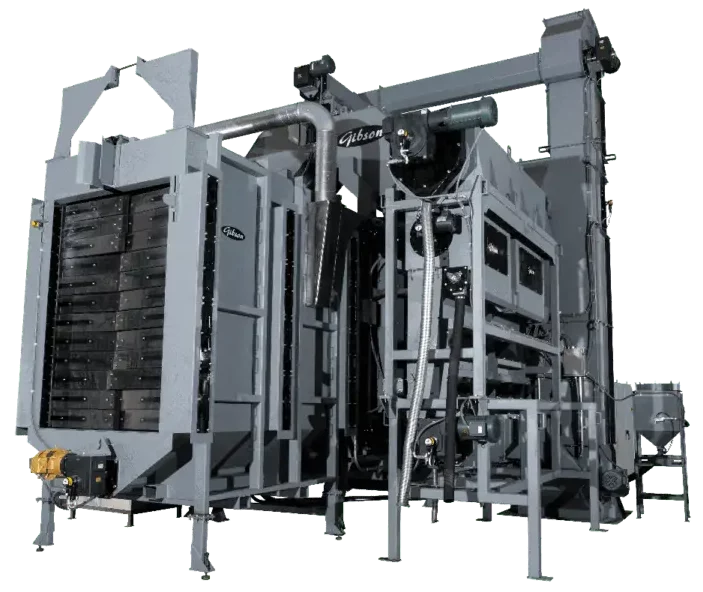

Dual Chamber Spinner Hangers

Features:

- These abrasive wheelblast systems have two work chambers mounted on an indexing turntable. One chamber is blasted while the other is open for loading and unloading.

- Hangers rotate within the blast chamber to ensure uniform coverage.

- Include PLC programming, cast liners on chamber walls, and a safety bump bar strip.

- Options include a variable frequency drive for blast wheels, a rotary scalping screen, a safety light curtain, and abrasion-resistant liners.

- Hanger capacities range from 125 to 2,000 pounds.

Benefits:

- Allow for speed batch blasting of sensitive parts while also continuing to work during loading.

- Provide 360° workpiece coverage.

- Improve quality and efficiency in cleaning, peening, prepping and finishing of workpieces that can be mounted on hooks.

Applications:

- Ferrous and non-ferrous castings

- Heat treated parts

- Automotive parts

- Die Castings

- Deflashing plastic

- Descaling

- Peening

- Deburring

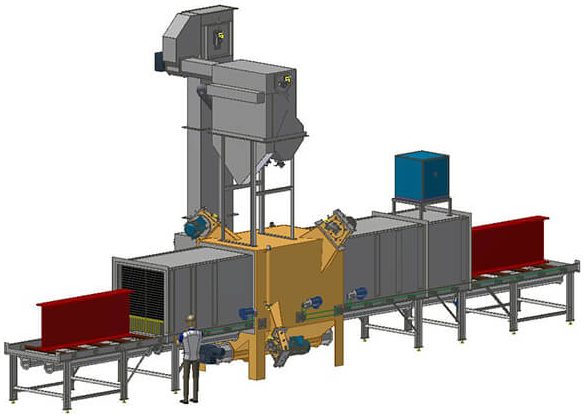

Wire Mesh Belt Blasters

Features:

- These systems use a wire mesh belt to convey parts through the blast chamber.

- Can be integrated with other machines to automate a process.

- Various belt widths and with multiple blast wheels and horsepower.

Benefits:

- Automate the process – reducing labor costs associated with batch-type blasters.

- Provide consistent results automatically.

- Versatile and rugged systems.

Pipe Blast System

Features:

- These are fully automated machines designed for cleaning pipe and other long and round materials.

- Skew roll conveyor that rotates parts 360 degrees as they travel through the blast chamber.

- Designed to remove rust and mill scale and create a surface profile for coating adhesion.

- Can handle pipe up to 42″ in diameter.

- Modular roller conveyors to accommodate different pipe lengths.

- Sensors control the flow of media to only blast when a pipe is present.

- 3/8″ manganese steel blast chamber with cabinet liner packages of rubber, AR400 plate, manganese steel, or cast chrome alloy.

- HMI controls to adjust the process and control the finish.

Benefits:

- Ideal for industries that repurpose used pipes, such as oil and gas, construction, and chemical processing.

- Ensure the entire surface of all pipes is fully cleaned.

- Save costs on wear parts and extend the life of the machine.

- Remove dust and mill scale and create a surface profile ready for coating.

Monorail Blast System

Features:

- These are fully automated systems designed for continuous 24-hour flow production.

- Can be customized to accommodate specific blasting needs.

- Manganese blast cabinets and cast alloy liners.

- Entrance and exit vestibules for abrasive containment.

- Multiple blast wheels positioned for optimum coverage.

Benefits:

- Ideal for high production rates of large fabrications, heavier parts, and cast parts.

- Automate cleaning or removing flash from die-cast parts.

- Streamline the shot blast process.

Applications:

- Blasting of Heavier Parts or Components

- Cast Parts

- External Finishing

- High Production Rates

- Large Fabrications

- Sand Removal

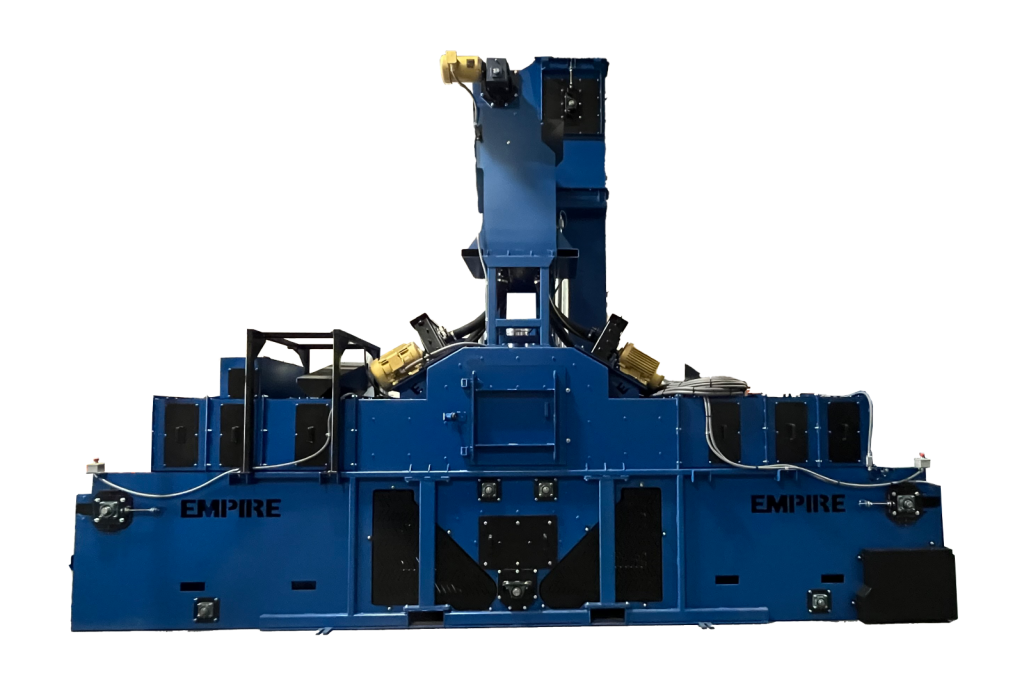

Roller Conveyor Wheel Blast System

Features:

- These are fully automated systems designed for 24-hour production.

- Used for blasting heavier parts at high rates.

- Can be easily integrated into production lines, such as paint lines.

- Many different blast envelopes with multiple blast wheels and horsepower.

- Some systems include skew rolls for cleaning pipes and other long, round materials.

Benefits:

- Reduce labor costs normally associated with batch-type blasters.

- Deliver consistent results automatically.

- Can be used for mill scale removal, structural steel, paint preparation, profiling, and inspection.

Applications:

- Inspection

- Mill Scale Removal

- Paint Preparation

- Profiling

- Structural Steel

Dust Collectors

Available Options:

- Photohelic Gauge

- Magnehelic Gauge

- HEPA Filters

- After Filters

- Silencers

- Abrasive Resistant Inlets

- Reverse Pulse

- Rotary Air Locks

- Explosion Vents

Standard Dust Collector Sizes:

- *Optional Sizing Quoted Upon Request*

- 1200 cfm

- 2000 cfm

- 500 cfm

- 800 cfm

Replacement Parts & Assemblies

Below is a list of some of the common replacement parts we manufacture for Wheel Blast Equipment:

- Elevator Belts

- Tune Up Kits

- Bearings

- Shafts

- Bushings

- Blades

- Seals

- O-Rings

- Weatherstrip

- Air Cylinders

- Gear Reducers

- Filter bags

- Hoses

- Tubing

- Hanger Rods

- Air Fittings

- Filter Cartridges

- Motors

- Liners

- Impellers

- Buckets

- Bubs

- Valves

- Bolts

- Flange Adapters

- Sheaves

- Pins

- AMP Meters

- AND MORE…

We also offer quality aftermarket parts for Goff, Coyote, Pangborn, Wheelabrator, Viking, and Bronco.

View Parts Proudly Serving Since 1986

Proudly Serving Since 1986